Technology and Patents

Astrea is the brand name of the high end photobioreactors, in reference to the goddess of Greek mythology, in which she embodies purity and integrity.

The basis of the practice tried-and-tested Astrea photobioreactors is a closed circulation system, which, using efficient thin-film technology with minimal energy consumption, provides optimal growth conditions for phototrophic microorganisms. This innovative technology is protected worldwide by the patent WO 2010/115412 A29.

Process specifications of photobioreactors

- suitable for fresh, brackish and salt water

- temperature range of 5 to 45°C

- pH range 1 to 12

- disinfectable with hydrogen peroxide and chlorine

- simple, modular scale up

- suitable for a variety of microalgae species e.g.: Nannochloropsis, Tetraselmis, Phaeodactylum, Haematococcus etc.

Technical characteristics of the Astrea reactors

- Plant size

- Astrea 30…200K 24…205,000 L production capacity

- glass tube diameter

- 39.6-60.6 mm

- Cultural volume/floor space

- 61…110 L*m⁻²

- Glass material

- Borosilicate (degree of transmission > 95%, lifespan ≥ 50 years)

- Glass tube wall thickness

- 1.8…3.2 mm

- Glass tube loops

- 11…355 m

- Number of modules

- 1…32

- module length

- 1…100 m

- Glass tubes in the module

- 1…48

- Glass tube spacing

- 130…152 mm (vertical in module)

- Glass tube spacing

- 156…178 mm (horizontal in the module)

- Module distance

- 500…1,000 mm

- System vessel

- Stainless steel/PE, 5…9,000 L

- System pump

- Stainless steel/Noridur ® 1.4593 (duplex stainless steel), 5…1,200 m³*h⁻¹

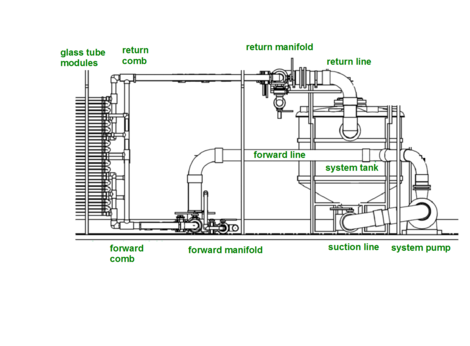

The reactors consist of three basic units:

Photosynthesis modules with horizontally arranged glass tubes,

- glass tube construction for the formation of long tube loops

- glass tube arrangement with a support plate system for the carrier, fixation and height adjustment of the glass tubes

- stranding for stabilization of the module system

Inoculation and running of a PBR

a long-term stable and innovatively built supply unit

- functional system vessels for optimization of substance exchange processes

- CAD-based engineering of manifold and collector systems

- algae-adapted and process-validated system pump

- process-optimized peripheral interfaces

a modern product-specific process control unit

- measurement and regulation of optical density, pH, temperature, level

- Measurement of oxygen and fluorescence

- light-dependent pump speed

- Data recording, exchange, remote access and export of process data via a web server

Reference plant projects

Astrea 115 K

- Client

- Simris Alg, Hammenhög, Sweden

- Floor area

- about 1,900 m²

- Volume

- about 120 m³

- Built

- 2016

Astrea 2KC

- Client

- Salata AG, Ritschenhausen, Germany

- Floor area

- about 30 m²

- Volume

- about 2.1 m³

- Built

- 2010

PBR 15K…50K

- Client

- Salata AG, Ritschenhausen, Germany

- Base area

- about 1,900 m²

- Volume

- about 85 m³

- Built

- 2005/2006